What is Ground Penetrating Radar New England?

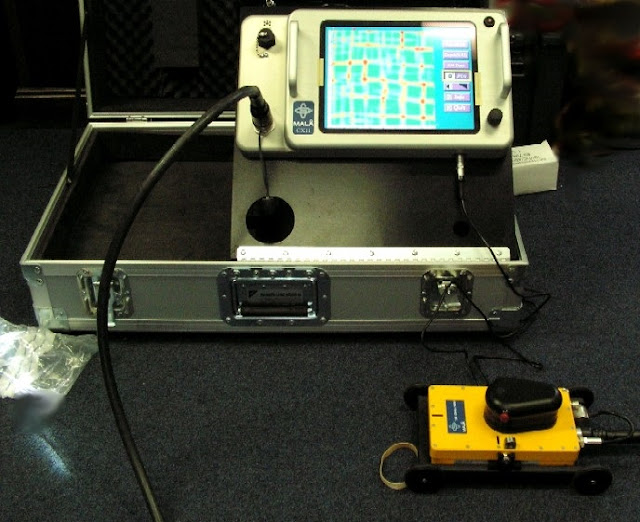

A surveying technique called ground penetrating radar New England employs electromagnetic radiation pulses to examine the sub-surface. It provides a non-invasive and non-destructive means of subsurface surveying. As a result, it is a helpful survey method to examine numerous items. Electromagnetic pulses are sent into the ground via a GPR transmitter. Different permittivity is used to identify subsurface changes. A portion of the electromagnetic energy is transmitted back to the surface whenever there is a change in the subsurface. These aid in identifying the traits that have been found by the technical team of ABC Testing Incorporated.

The science behind Positive Material Identification New England:

The inspection of a material, often a metallic alloy, to determine whether it is consistent with the user's request is known as Positive Material Identification New England. Everyone in the supply chain can adhere to standards by knowing an alloy's precise composition and grade. Along the supply chain, suppliers, distributors, facility staff, manufacturers, and other accountable parties all come into contact with the materials. Consider the harm faulty metals can wreak on a wider scale if one poor metal component can result in a huge conflagration. Additional non-destructive and destructive testing can be performed depending on what the metal will be used for.

How to use NDT Penetrant Massachusetts?

The non-destructive testing technique known as Penetrant Massachusetts is used to find surface flaws that are undetectable to the unaided eye. It is determined in terms of liquids' capillary characteristics. By creating indicator designs on the face of the examined products, this technique identifies faults. These patterns are wide enough to cover the faulty aperture and have a great visual contrast. A particular soaking liquid is applied to the exterior of the tested object prior to testing. These liquid fills surface imperfections' voids by the action of capillary forces before leaving the examined region.

Importance of Welder Qualification New England:

A detailed response is impossible since welding credentials apply to such a diverse range of industries, each of which is governed by its own set of laws, standards, and norms. A holder of Welder Qualification New England who joins metals is a certified welder. Welders utilize welding equipment and comprehend technical drawings and plans. A wide variety of metals, including iron, steel, aluminium, stainless steel, and brass, are among those they can deal with. The construction, manufacturing, shipbuilding, aerospace, and automotive sectors all rely heavily on welders. They collaborate with project managers, designers, site engineers, and other fabricators.

.jpg)

No comments:

Post a Comment